The mitigation of global warming is one of the most important, urgent and challenging tasks for mankind and it requires a huge collective effort. To address the problem, the EU has set CO2-emission reduction objectives for 2030 and 2050, which require a serious consideration of how steel shall be produced in the future.

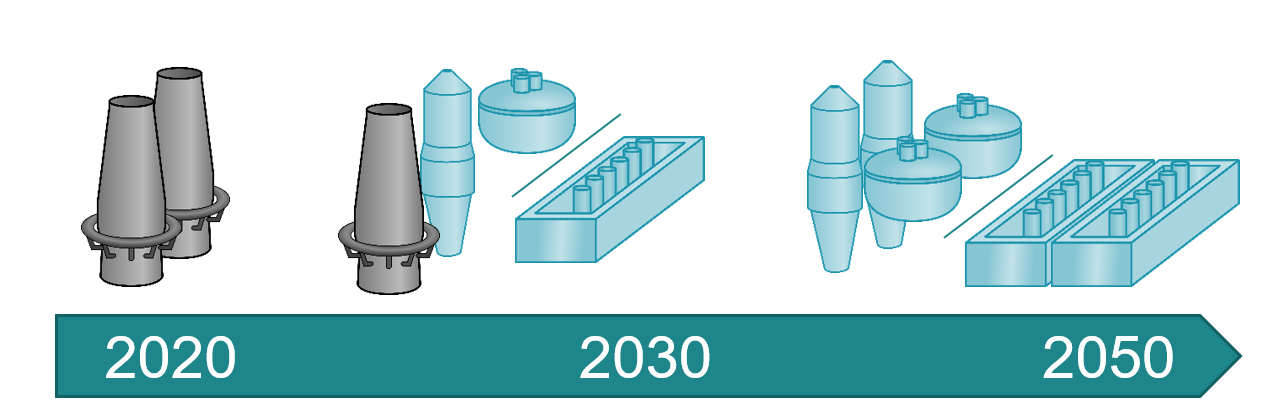

All major European steel producers have published roadmaps on how they plan to reach the defined objectives [1][2][3][4][5][6][7][8][9]. In general, the roadmaps base on step-by-step replacement of the blast furnace (BF) process by other, mostly hydrogen-based reduction furnaces. However, due to global economic constraints and limitations concerning the availability of green electric energy and hydrogen, as well as the fact that BFs have campaign lengths between 10-20 years, these roadmaps for CO2 mitigation still include the BF process even beyond 2030 (cf. Figure 1). Consequently, a fast and significant mitigation of CO2 emissions from BF ironmaking is an essential requirement. The gradually increasing availability of hydrogen or hydrogen-rich gases, direct reduced iron (DRI) and hot briquetted iron (HBI) gives new opportunities to mitigate BF CO2 emissions. The general objective of this proposal is to identify new opportunities to decrease CO2 emissions of BF ironmaking by 25-35%. This shall be reached by high injection rates of hydrogen-rich materials and by simultaneously compensating for the expected downsides (such as higher heat demand) by charging of DRI/HBI or by injection of hot shaft gas. These concepts will require operating the BF at setpoints where no practical experience yet exists. The main technical objective of H2transBF2030 is to develop methods and tools to systematically identify fast CO2 mitigation measures and to effectively master the resulting new BF operation setpoints.

Figure 1: Technical scenarios of roadmaps for CO2 mitigation until 2030 from major European steel producers [1][2][3][4][5][6][7][8][9]

The participation of the four dominating steel producers in Europe in H2TransBF2030 emphasizes the importance of the project and ensures optimum implementation of its results. To guarantee the feasibility of the work, key European research centres for BF ironmaking as well as two universities will take part in the project, bringing an excellent experience into the consortium. The project approach will combine industrial demonstration of injection of hydrogen-rich gases, laboratory trials with high hydrogen concentrations and DRI/HBI, modelling and simulation to systematically identify bottlenecks and consider overall effects on downstream process as well as tools for operation guidance at the new operating points. The survey of the international state-of-the-art that follows is focused on these fields.

References

- Hydrogen meeting future needs of low carbon manufacturing value chains (H2Future), https://cordis.europa.eu/project/id/735503/de (last visit 25.08.2021)

- Exploitation of projects for Low-Carbon future steel industry (Low Carbon Future), 2020, RFCS Project Grant Agreement N. 800643. [Online]. Available: https://www.lowcarbonfuture.eu/download/.

- GREENSTEEL (running project)

- Reiprich, N. Mit Wasserstoff zur klimaneutralen Stahlproduktion. stahl und eisen 6 (2021) 24–26.

- Hybrit, https://www.hybritdevelopment.se/en/, last visit 25-08.2021

- https://www.tatasteeleurope.com/sustainability/carbon-neutral-steel, last visit 25.08.2021

- https://www.thyssenkrupp.com/de/newsroom/pressemeldungen/weltpremiere-in-duisburg–nrw-wirtschaftsminister-pinkwart-startet-bei-thyssenkrupp-versuchsreihe-zum-erstmaligen-einsatz-von-wasserstoff-im–hochofen-17280.html, last visit 27.08.2021

- https://www.industrytransition.org/green-steel-tracker/

- Kinzel, P. New technological approach for blast furnace plants to achieve important CO2 mitigation. 5th ESTAD Conference. 2021