To save CO2 emissions many steel producers have announced or already started to inject hydrogen or hydrogen containing gases into the BF. Although natural gas and also coke oven gas injection have been practised over a long time at sites where those injectants are available at competitive prices, only few publications, deliveringa holistic data analysis from industrial blast furnace operation with a higher share of hydrogen based ore reduction, are available.

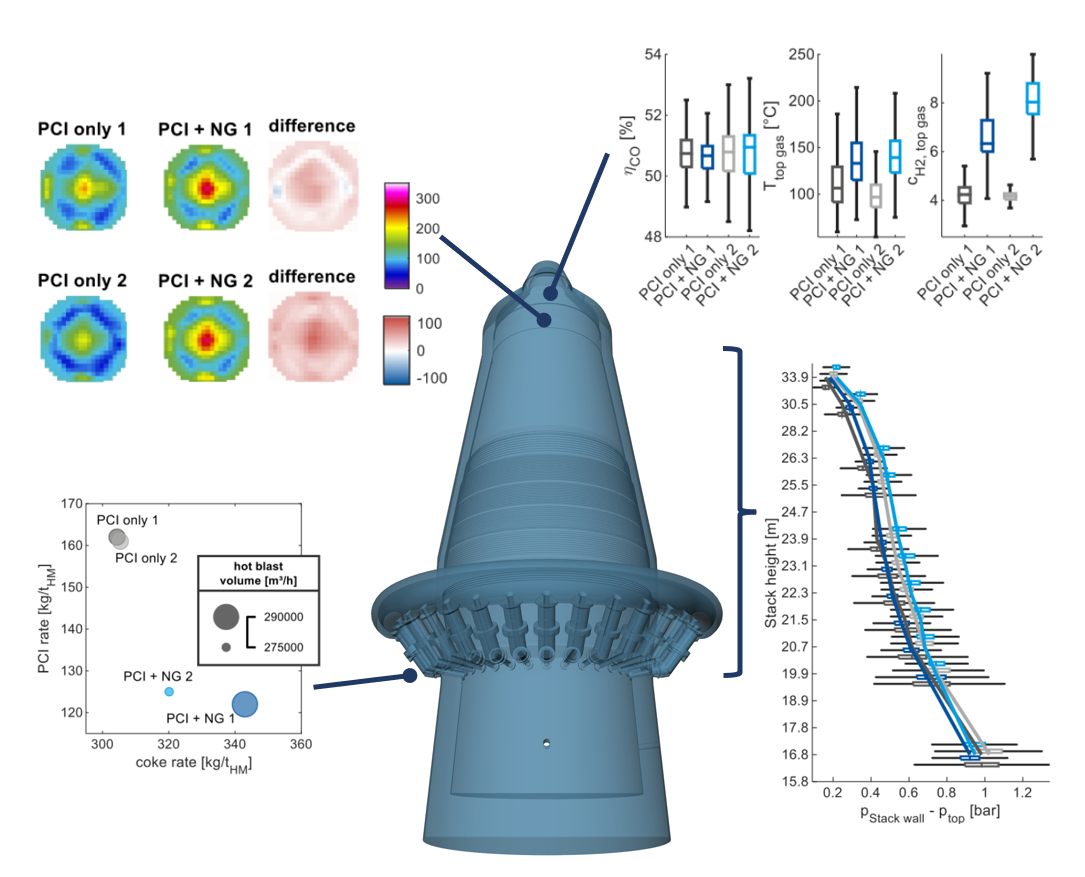

In the H2TransBF2030 project a systematic comparison of blast furnace data of two operational periods with natural gas and pulverised coal injection to two periods of only pulverised coal injection has been carried out. Comparisons from data received from measurements located at the furnace, from the top, from the shaft, belly and bosh walls as well as from the in-burden probe were evaluated.

The study shows, that the NG injection had an influence on the blast furnace processzones as well as on the operational working state. Non-ideal operational states were more seldom during natural gas injection.

The results of the study have been published on 6th European Steel Technology and Application Days 2023 in Düsseldorf. Read the full conference contribution on research gate:

(PDF) Influence of a higher hydrogen-based reduction share on the Blast Furnace process derived from analysis of data during natural gas injection periods.

Available from: https://www.researchgate.net/publication/372078156_Influence_of_a_higher_hydrogen-based_reduction_share_on_the_Blast_Furnace_process_derived_from_analysis_of_data_during_natural_gas_injection_periods [accessed Feb 26 2024].